Alum Composition and Types

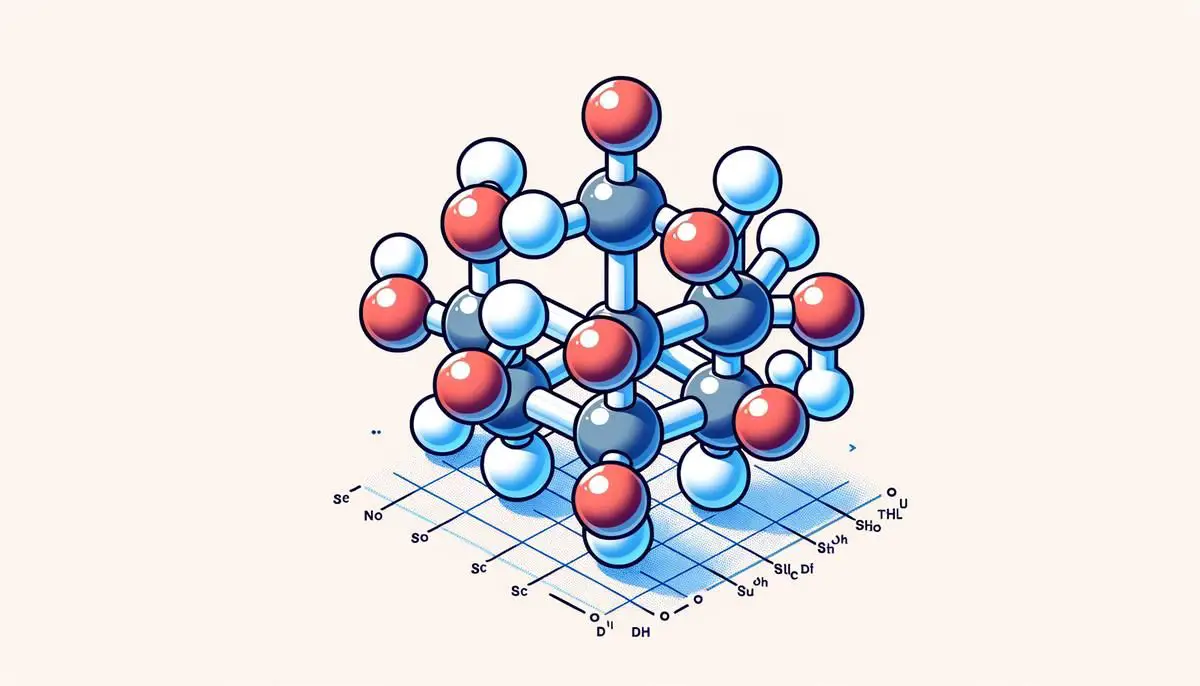

Alum, a double sulfate salt, combines aluminum sulfate with a monovalent metal sulfate, typically potassium or ammonium. The general formula for alum is MAl(SO₄)₂·12H₂O, where M represents the monovalent metal.

Potassium alum, or potash alum (KAl(SO₄)₂·12H₂O), is widely used in various applications, from food preparation to pharmaceuticals. Its hydrated form ensures stability and effectiveness.

Ammonium alum (NH₄Al(SO₄)₂·12H₂O) substitutes ammonium for potassium, making it favorable for protein-based materials in industries like dyeing and leather tanning.

Sodium alum (NaAl(SO₄)₂·12H₂O) is less common but valuable in specific sectors such as papermaking and firefighting foam. Sodium's inclusion alters properties like solubility, influencing its suitability for different applications.

Other alums, like chrome alum and selenate alums, diversify the category by introducing varied metals and anions into the classic alum structure to tailor properties to precise industry needs.

By selecting the ideal alum type based on molecular configurations and resulting properties, industries can optimize processes from water purification to textile manufacturing.

Alum in Industrial Applications

Alum's attributes translate to practical applications across different industries.

- Water purification: Alum acts as a flocculating agent, clumping impurities for easier removal of solids from water, which is vital in municipal water treatment facilities.

- Textile industry: Potassium alum and ammonium alum are used in the mordanting process to fix dyes onto fabrics, contributing to vibrant, long-lasting colors and enhanced durability. The specific type of alum chosen can affect the resultant hue and fabric hand.

- Food industry: Potassium alum (E522) assists in keeping certain foods crisp and visually appealing, such as maintaining the firmness of pickles during the pickling process. It also serves as a component in baking powder, contributing to texture and volume in baked goods.

Alum's affordability and efficacy make it attractive on a commercial scale, playing a significant role in the day-to-day operations of various sectors while having a relatively low environmental impact compared to other chemicals with similar applications.

By recognizing the unique benefits of each alum type, industries can optimize their operational efficiency while maintaining sustainability.

Health and Safety Concerns with Alum

While alum is generally recognized as safe under typical usage conditions, exposure to alum dust or concentrated solutions can cause irritation to skin, eyes, and respiratory systems.1 These risks are commonly mediated by guidelines surrounding industrial hygiene practices, such as personal protective equipment (PPE) and adequate ventilation systems.

Chronic exposure to high levels of aluminum compounds may pose additional health risks, but conclusive evidence directly connecting exposure to specific health problems remains elusive.2 Regulatory bodies like the Occupational Safety and Health Administration (OSHA) in the United States have set permissible exposure limits (PELs) to protect workers in industries where alum use is prevalent.

The Food and Drug Administration (FDA) in the U.S. has approved potassium alum as a food additive, underscored by its long history of use in food preservation, medicinal, and cosmetic applications.3 However, the inclusion of such compounds in consumer products necessitates rigorous evaluation to ensure safety and adherence to prescribed concentration limits.

Industries relying on alum should adhere to regulated guidelines and engage in consistent training for personnel on proper handling and potential risks. Careful management of exposure scenarios and ongoing industry education efforts are crucial in sustaining the balance between utilizing alum's beneficial properties and safeguarding against potential health risks.

- National Center for Biotechnology Information. PubChem compound summary for CID 24856, Aluminum potassium sulfate dodecahydrate. https://pubchem.ncbi.nlm.nih.gov/compound/Aluminum-potassium-sulfate-dodecahydrate.

- Krewski D, Yokel RA, Nieboer E, et al. Human health risk assessment for aluminium, aluminium oxide, and aluminium hydroxide. J Toxicol Environ Health B Crit Rev. 2007;10 Suppl 1:1-269.

- U.S. Food and Drug Administration. CFR – Code of Federal Regulations Title 21. https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=182.1129.